We talk about the five new ways of the artificial intelligence logistics industry today.

Artificial intelligence is playing a pivotal role in revolutionizing the logistics industry.

Thanks to globalization, everything is becoming more and more digital; consumers are buying more goods online and expecting their products or services to be delivered faster and for less money.

In today’s fast-paced world, logistics, and supply chains must adapt to rapidly changing consumer demands. According to ML News, the supply chain wastes hours a day on paperwork, resulting in a loss of more than $170,000 annually.

Using artificial intelligence in specific tasks is one way to improve the problem. Shifting certain manual activities to machines can help alleviate the problem of paper paperwork while also increasing productivity.

In this article, you will learn how AI can contribute to the logistics industry.

The impact of artificial intelligence logistics

Artificial intelligence has fundamentally changed the logistics and supply chain industry. Here are five ways AI-driven technologies can help companies enhance and innovate their logistics and supply chain operations.

1. Robotics of artificial intelligence logistics

Robotics refers to the use of intelligent machines in the supply chain management process. According to Statista research, logistics service robots will generate more than $6 billion in revenue by 2021.

Robots typically perform routine operations such as delivery, transportation, storage, picking, packaging, and routing. The main difference between ordinary industrial robots and artificial intelligence-assisted robots is that the latter can perform more complex tasks without human intervention.

Intelligent robots can also evolve by learning new tasks and performing increasingly complex behaviors. The equipment can partially, and in some cases wholly, replace humans in the distribution process, making it more predictable, easy to supervise, and successful.

For example, drones can transport a certain number of loads and fly or move over land or water.

RFID (radio frequency identification) solutions can sort, identify and deliver items autonomously through warehouses. As a result, robotics in logistics can increase throughput while also making it easier for humans to manage all delivery stages.

2. Self-driving cars of artificial intelligence logistics

Self-driving cars have the potential to improve delivery efficiency significantly. The technology has the potential to improve reliability, cost efficiency, and predictability. Although we have not yet acquired fully autonomous delivery vehicles, it is only a matter of time.

As technology advances, it is conceivable that shortly, consumers will receive their shipments without human intervention.

According to McKinsey research, self-driving cars and drones, in particular, will deliver more than 80 percent of packages. By overcoming transportation barriers and inconveniences, this technology will improve the efficiency of the delivery process.

3. Computer Vision of artificial intelligence logistics

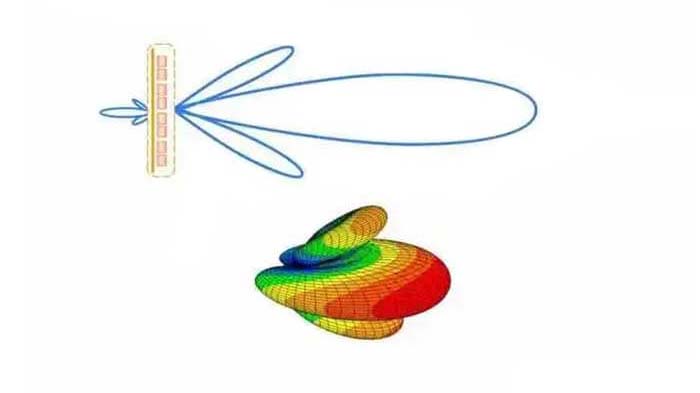

Every vision system consists of two main components: the camera and the brain-computer that controls everything.

It can detect objects, goods, specific activities, and colors and perform operations based on sophisticated algorithms. Computer vision can use the technology to identify damage and increase productivity in the production process.

For example, Amazon uses a computer vision-based artificial intelligence system to unload a trailer in 30 minutes instead of the hours it would take without one.

In addition, the computer vision-enabled system can automatically detect damage, determine the cause of the damage and its severity, and take steps to prevent future cargo accidents.

Loading and unloading products is another application of computer vision. This technology not only identifies and locates items and packages in the store but can also do so autonomously.

With this in mind, machine learning systems are widely used to reduce customer churn, improve the quality of the supply chain and increase the security of the delivery process.

4. Predictive Analytics of artificial intelligence logistics

Any logistics company must operate efficiently, deliver on time, and save on transportation costs. In-depth research based on historical data is required to detect risk trends, implement corrective steps and generate forecasts.

Using predictive analytics, you can only significantly enhance logistics operations, modify shipping patterns, pay on delivery, and predict consumer behavior.

The MHI2020 annual industry survey shows that the percentage of logistics companies using predictive analytics jumped from 17% in 2017 to 30% in 2019.

Not only can it improve supply chain visibility, optimize routes and make it easier to track and plan shipments, but it can also identify surprises and hazards. If appropriately implemented, it will significantly reduce operating expenses and help companies make more informed decisions.

5. Big Data of artificial intelligence logistics

As with all other operations, artificial intelligence logistics generates a lot of data. Without a well-maintained data management system, handling all of this material can be even more difficult.

Companies can save money and avoid late shipments and deliveries by collecting data from multiple sources, such as driver applications, equipment, and systems and evaluating how various factors affect the delivery process.

You can drill down into historical delivery statistics, and driver ratings and use big data analytics to make changes. According to this study, more than 91% of Fortune 1000 companies are investing in big data.

In addition, AI-driven data analytics allows companies to consider variables such as fleet maintenance schedules, vehicle sensors, inclement weather, and fuel costs.

Not only does it provide drivers with destination ideas and help them travel more efficiently, but it also allows companies to reduce logistics costs on a route-by-route basis.

Conclusion of Artificial Intelligence Logistics

Artificial intelligence logistics uses new ways to process data and improvements throughout the supply chain. Predictive analytics, robotics, computer vision, deep learning, and self-driving cars are examples of technologies that can dramatically improve logistics and supply chain performance.

They can change the way items are managed in warehouses and optimize last-mile delivery and logistics networks. With this in mind, logistics and supply chain companies can look to these technologies to improve efficiency and reduce costs.

Besides the 5 New Ways of the Artificial Intelligence Logistics article, you may also be interested in the below articles.

Internal Antenna VS. External Antenna

LTE Vs. 5G: Is 5G Better Than LTE?