RFID sensor tags can transmit information to RF readers within a certain distance so that warehouses and workshops no longer need to use handheld barcode readers to scan barcodes of components and work-in-progress one by one, which to a certain extent reduces the occurrence of omissions and significantly improves the efficiency of staff.

The logistics industry is an important part of China’s national economy. In 2019, China’s total social logistics reached 298.0 trillion yuan, up 5.9% year-on-year. In the context of the development of Internet+ and Industry 4.0, the supply chain of China’s logistics industry has also ushered in a new opportunity for intelligent and digital upgrading and transformation.

Right now, China’s digitalized supply chain has entered a high-speed development stage. The use of digitalization and intelligence to transform the supply chain and create a new logistics supply chain competitiveness has become an important strategy for the development of enterprises.

Along with the Internet e-commerce promotion and manufacturing industrial revolution 4.0, logistics enterprises are now actively building their own integrated supply chain model, providing consumers with a good shopping experience while also actively building the introduction of new technologies and new platforms.

In fact, sharing information throughout the supply chain enables companies to accurately predict the possibility of inventory shortages and make timely replenishments to avoid any delays that may result, ensuring synchronization of planning and execution from start to finish.

Through supply chain collaboration, companies can reduce the size of their inventories, shorten the payback period, improve the quality of their products and services, and speed up their response to the market.

RFID sensor tags can transmit information to RF readers within a certain distance so that warehouses and workshops no longer need to use handheld barcode readers to scan barcodes of components and work-in-progress one by one, which to a certain extent reduces the occurrence of omissions and significantly improves the efficiency of staff.

As can be seen, the application of RFID sensor tags in such a cold chain transportation processes has obvious advantages. Including automatic identification, data security, automatic monitoring, and so on.

Of course, this is only the application of temperature sensors, humidity, pressure, light display, etc. have their specific application scenarios to help achieve some specific functions, integrated with these functions of RFID packaging, which can provide more possibilities for visual logistics.

The traditional supply chain is characterized by information silos and non-real-time information exchange, making it difficult to achieve supply chain transparency and visualization.

With the addition of IoT, cloud computing, and big data technologies, the traditional serial chain supply chain system is transformed into a parallel mesh digital supply chain, which can realize real-time visualization of goods in storage, in transit, and in production, thus continuously optimizing and improving the existing supply chain system.

RFID sensor tags sensing platform combined with the capital side, through the interconnection platform can provide the real transaction data of logistics, information flow, and capital flow between the upstream and downstream of the industry, and ensure the return of funds to form a closed operation.

To open the capital financing, and resource needs, create a platform for transaction data, logistics services, and inventory services, to achieve a high degree of integration of modern logistics and now information systems, is also a major direction of industry development.

Ultimately, RFID sensor tags can transmit information to the 10-foot range on the radio frequency reader, so that warehouses and workshops no longer need to use handheld bar code readers on components and work-in-progress to scan bar codes one by one, which to a certain extent reduces the occurrence of omissions and significantly improves efficiency.

In terms of cold chain logistics, along with the continuous improvement of domestic consumption level, the development of the domestic cold chain logistics industry has entered a new stage, and the development scale of cold chain logistics will maintain the growth trend in the future.

The tightening of industry regulation, the in-depth application of modern technology, and green development will become the main development trend in China’s cold chain logistics industry. Promoting the transformation and upgrading of cold chain logistics is also an important breakthrough to promote the whole logistics industry to achieve improvement.

From the development trend of the whole supply chain field, the whole supply chain infrastructure is now expanding from a commodity supply chain to a service supply chain and has developed to a new stage of intelligent supply chain with the deep integration of the Internet and Internet of Things, and the social cost is further reduced. In a few years, logistics supply chain management is expected to open a new model of transparency and security.

Besides the Advantages of RFID Sensor Tags in the Logistics Industry article, You may also be interested in the below articles.

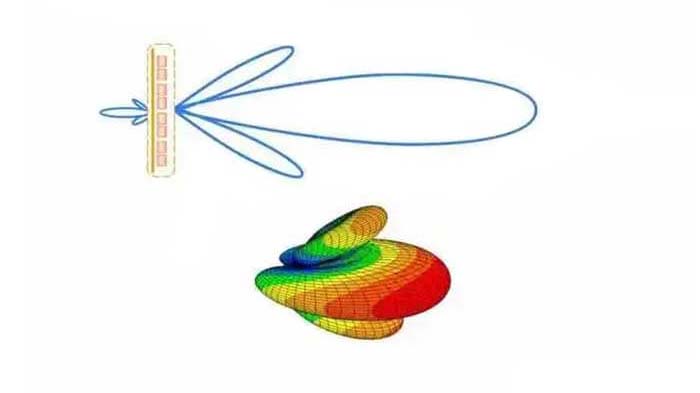

Internal Antenna VS. External Antenna

LTE Vs. 5G: Is 5G Better Than LTE?