Metaverse is a new concept and the trend of thinking is still continuing to ferment. This week there are more companies laying out and voicing around the metaverse.

With more and more companies entering the game, the meta-universe has long since moved away from science fiction and delved into the industrial sector, incorporating more and more technologies and products that are compatible with multiple dimensions and fields, gradually forming a new mega-industrial ecology built by multiple builders.

Whether it is technology iteration, industrial change, or financial evolution, the meta-universe provides an ultimate vision that contains a holistic set of technological, market, and financial solutions. Dividing the physical and virtual worlds into four quadrants according to the digital and real identities of people, the metaverse includes:

Digital native

Things are constructed in the virtual world by people participating as digital identities, in a purely fictional form, with no correspondence to the real world.

Reality recurrence

Things in the virtual world, in which people participate as digital beings, reproduce things in reality that may have currently existed or existed in the past.

Digital twin

The participation of a person in a realistic capacity, the digital twin by mapping real things in the virtual world, thus digital twin is reflecting the full life-cycle process of the corresponding physical equipment.

Transcendental reality

People participate in reality to enhance, improve and enrich the real world by computing and analyzing the real world in the virtual world. According to the four quadrants, we can divide the meta-universe into the social meta-universe and the industrial meta-universe. The industrial metaverse focuses on the left side of the axis, transforming and enhancing people’s experiences and lives in the real world through the virtual world.

Industrial Metaverse Definition

Industrial Metaverse is a new ecology of deep integration between new information and communication technologies and the real economy represented by the Internet of Things, artificial intelligence, and digital twin, whose ultimate goal is to promote the efficient development of real industry and build a new manufacturing and service system covering the whole industrial chain and the whole value chain.

The industrial metaverse, a precise reconstruction, and re-creation of social and physical attributes in the real world by the digital world is the materialization of artificial intelligence in the real world, moreover, it is an important part of the real world and real economy.

As an interface for the introduction of digital capabilities into the real world and the real economy, the industrial metaverse will be a new generation of discovery tools, efficiency tools, and innovation tools for realizing the transformation and upgrading of enterprises’ hard technologies.

Of course, the beautiful vision proposed by the industrial metaverse needs to be integrated into applications and scenarios by way of integration and innovation.

The functions of industrial metaverse

The industry is the universe, as a digital ability to introduce the real world, the entity economy interface, more than just use the digital world to reconstruct the physical properties and social attributes in the real world, and pay more attention to the improvement of the reproduction of the real world.

The industrial dollar universe will become an important part of the entity economy. In this new industrial numerical revolution, the industrial dollar universe will extend extension and intelligent technology in the depth and breadth of industrial landing, accelerated technology and depth of the industry, Stimulate the vitality and creativity of the entity economy.

Industrial metaverse Development

The industrial metaverse will be supported by five major aspects, including data foundation, simulation engine, digital intelligence core, hardware carrier, and open collaborative ecology. The in-depth combination of its technology and industry will promote two major innovations of production paradigm and optimization paradigm in the future.

Five major supporting elements

- The database includes digital device information, enterprise information, Internet information, and human social behavior information, etc.

- The engine is the simulation capability, rendering capability, and computing capability, which supports the physical correctness and real-time nature of the meta-universe.

- The core is big data technology and artificial intelligence, which provide intelligent perception and cognitive capabilities, including learning, optimization, creation, etc.

- The carriers are intelligent interactive devices, Internet of Things devices, new materials, and new general-purpose hardware devices, such as general-purpose robots, which are the hardware basis for the digital-real integration capabilities.

- The form of an industrial meta-universe is an open ecology with the collaboration of the whole society. In the era of the metaverse, compatibility, openness, and interoperability among products will become the core elements to guarantee user experience. Cross-company and cross-industry collaboration and extension of the industrial chain will bring an exponential increase of metaverse content and value, and the value of collaboration will be more prominent, which will give rise to a prosperous, open, and collaborative co-construction ecology.

Two major metaverse industrial revolutions

First, the industrial metaverse revolution of the production paradigm

From the original iteration in the real world, it is upgraded to mapping problems in the real world to the meta-universe, finding relevant solutions in the meta-universe, and then deploying the optimal solutions generated through simulation back to the real world.

The industrial metaverse replaces physical costs with computational costs, thus expanding the scope of solutions that the real economy can try, while seamlessly integrating the optimization capabilities of artificial intelligence to significantly reduce the cost of innovation, stimulate the vitality of the industry, and unleash the potential of innovation.

Second, the industrial metaverse revolution of the optimization paradigm

The application of industrial meta-universe technology, on the other hand, breaks down data silos and gives a unified form of expression and data interaction protocol to the originally fragmented production links, thus enabling the seamless flow of information and collaborative optimization of each link, transforming and upgrading the single-point optimization paradigm into a collaborative optimization of the whole chain, and transforming the efficiency of industrial upgrading from additive growth to multiplicative growth and exponential growth.

Technology Phase

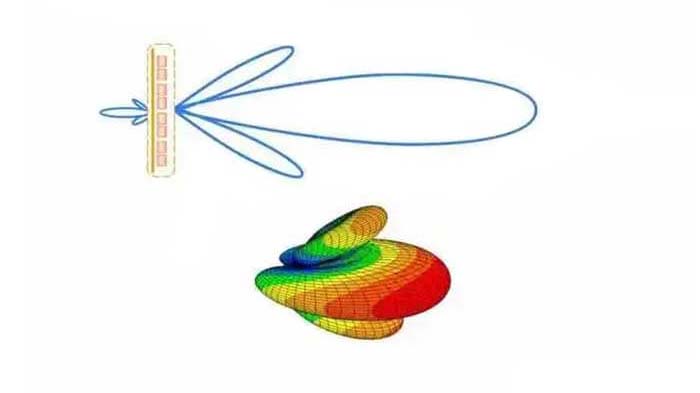

These are digital twin, digital companion, and digital native. Specifically, the digital twin stage, led by “replication”, mainly combines 5G, the Internet of Things, blockchain, cloud computing, artificial intelligence, and other technologies to accurately describe the real-world objects in the virtual world.

Digital Twin

The initial stage is the digital twin, and I think this concept is very familiar to everyone. In this stage, it is mainly through the integration of digital technologies such as ABCDE+5G to reconstruct objects in the real world in the virtual world accurately.

Digital Accompaniment

Digital companion is the next stage, in which the theme is to deeply integrate the optimization ability of artificial intelligence and industry, establish a two-way connection between virtual and reality, map the problems in the real world to the digital world, make optimization adjustments in the digital world, and then map our optimal solutions in the digital world back to the real world so that we can accelerate the rapid growth of the real industry with digital technology.

Digital Native

The advanced stage of industrial metaverse development is a digital native. The theme of this stage is the independent learning and innovation capability of artificial intelligence and the development of new hardware systems to enhance the hardware carrying capacity of the real world.

Through the development of new materials, processes, and devices (e.g., general-purpose robots, etc.), the real world is empowered to deploy more creative digital solutions.

In a nutshell, by using reinforcement learning technology at this stage, AI will have the ability to automatically discover new connections and foresee new opportunities in the highly realistic digital world to achieve seamless integration of the digital and physical worlds.

As each industry has different degrees of digitization, automation, and intelligence, the three major technological stages of the industrial metaverse do not develop in a fragmented manner, but jointly form a new ecology with multi-level and multi-stage parallel development.

The focus of industrial metaverse is on service scaling

As a subset of the metaverse, the industrial metaverse needs to meet the key characteristics of the metaverse.

The metaverse is built jointly by stakeholders;

The metaverse is built through large-scale collaboration;

the metaverse is an emergent, self-organizing economy;

that the builders of the metaverse participate freely and evolve to form new consensuses in independent digital identities;

The physical things in the metaverse are freed from the constraints of physical space, thus forming a digital world with an extreme abundance of various resources.

From these characteristics, it is clear that although the industrial Internet is the infrastructure of the metaverse, the infrastructure of the metaverse is not exactly the industrial Internet.

To be the infrastructure of the metaverse is not a simple superposition of various technologies, but should meet the criteria of the metaverse.

The main reason is that the industrial scene is generally somewhat closed, the industrial Internet is not built by a wide range of stakeholders, the development and definition of industrial products rarely incorporate user-created content, and large-scale universal collaboration has not yet been formed.

Manufacturing is an extremely complex process and the most critical step in the supply chain. Depending on the manufacturing strategy, companies continuously optimize their production process, which in general is divided into three types.

Make-to-stock (MTS) strategy

Producing or manufacturing goods based on expected consumer demand. This approach also uses forecasts and real-time data to help produce the right amount of product and ultimately reduce waste in the factory. Its main drawback is that it relies on forecasting and builds up a large inventory.

Make-to-order (MTO) production strategy

This refers to a company’s production schedule based on the demand and delivery dates of customer orders. Its purpose is to reduce inventory, not to make any inventory storage, and to schedule production only when there is an order and adjust production if there is no order. Products manufactured to order include computers, automobiles, heavy equipment, etc.

Flexible assembly production (make-to-assemble, MTA) strategy

This is a hybrid model of the first two strategies, allowing some components to be customized to customer needs. The production line stocks basic parts based on demand forecasts but does not assemble them until the customer places an order. A good example is the restaurant industry, for example, which prepares some raw materials and then waits for a customer order to start processing.

Regardless of the production strategy, all of them are designed from the producer’s point of view to improve the efficiency of production and operations, enhance the quality of products, and reduce inventory and lead times. However, these strategies that start with manufacturing are not production strategies that fit the characteristics of the industrial metaverse. There are two types of stakeholders in the industrial metaverse that will play an important role in the Industrial Internet.

Design service providers

Service providers provide design solutions for the layout of the factory or the products produced. There are two levels of design, the design of the factory itself, and the design of the manufactured products.

On the one hand, the factory itself needs to be redesigned and redefined in order to meet the needs of individual end-users, to be extremely flexible, to have the right layout for the various production facilities, to use the right communication and control devices, and to produce quality and cost-effective goods.

On the other hand, end-users may not know what they want and need professionals with design skills to improve consistency in design quality and reduce design risk.

End-users

End users vote for different customized products through their purchasing power in the process of buying products, thus making the explosive and explosive products stand out from the crowd.

The industrial metaverse will see a dramatic reduction in the difficulty of design and idea birth, and the number of product designs will grow exponentially. Just as the short video platform has created a large number of content creators, the average consumer will be able to easily render and simulate 3D prototypes of custom products at any time.

In the process, if the end-user provides a product idea, he or she can get the corresponding product sales revenue in the industrial meta-universe.

What people need is not a drill, but a hole in the wall; what people need is not a hole in the wall, but a painting hanging on the wall; what people need is not a painting hanging on the wall, but a beauty experience. The industrial metaverse allows people to feel the experience of beauty.

The production efficiency of machines no longer restricts the improvement of productivity; human knowledge, experience, innovation power, design ability, and serviceability become bottlenecks.

The more complex an industrial system is, the slower the learning curve of people becomes, and when the learning curve of people lags behind the progress of technology, people become the bottleneck that restricts the progress and application of technology.

The industrial metaverse realizes the transmission of people’s knowledge and makes it possible to scale up personalized and high-end services.

Production manufacturers will also transform in the industrial metaverse from producers of final products to providers of manufacturing-as-a-service, such as travel service providers and butler service providers.

The foundation of the industrial metaverse is CPS

The industrial metaverse can serve as a grand vision to solve the bottleneck of knowledge and service generation, utilization, and scale replication, and achieve a new breakthrough in value creation for industrial enterprises.

In the virtual digital space, various technologies continuously accumulate dynamic data and reconstruct the production process. The digital twin constructs a relationship between the physical world and the digital environment to retrace and predict the production process.

The realization of the industrial metaverse focuses on simulation and autonomous control. Options that are difficult to experiment with within the physical world can be performed in the industrial metaverse through parameter adjustment and plan changes.

It can be seen that the industrial metaverse is based on CPS.

CPS is an information-physical system, which can also be translated as Cyber-Physical System. The physical system represents the management and modeling of functionality, and the Cyber system is the management and modeling of the relational nature between entities, environments, and activities.

CPS is the deep integration of communication, computation, and control in Cyberspace with entity systems within all scales. CPS, with IoT as an important element, can connect links across the value chain, enabling players located at various locations in the chain to serve users directly at a very low cost, and also making collaboration between the chain in terms of services less costly.

CPS has achieved widespread application, and many products span both the physical and virtual worlds. For example, smartphones are the physical and the app installed on them is the virtual, machine tools, airplanes, cars…all are combining the value of the physical and the virtual.

The physical space is the various elements and individuals of activities that make up the real world, including environments, equipment, systems, clusters, communities, and people activities.

The virtual space is the synchronization and modeling of these elements and individuals, with a mirror space driven by real-time data, dynamically reflecting the entity state, simulating various relationships through the establishment of individual space, group space, environment space, and deduction space, forming decisions based on records, evaluation, deduction, and prediction, and constituting a complete knowledge application and knowledge discovery system.

Individual space

Obtain object mechanism data in the entity space, associate objects according to the mechanism, and establish quantitative analysis models by using the data to solve the problems of diversity and individual differences at a small cost.

Cluster space

Obtain cluster operation data in entity space, my universal laws from the data used by a large number of objects in different environments, and realize predictive and collaborative decision-making mechanisms based on the original control, information, management, and other traditional systems.

Environment space

Obtain internal and external environment data in the entity space, establish quantitative relationships between environment and individual/group effectiveness based on usage data in different environments, and address task diversity and environmental complexity.

Activity space

Obtain task activity data in entity space, extract activity features in group objects and correlate them for the activity state of objects in the environment, and achieve collaborative optimization of individual/group activities in the environment by facing multi-level and multi-dimensional task objectives.

Extrapolation space

Combining the relationship models between individual space, group space, environment space, and activity space, facing the multi-model space collaboration goals, forming multi-model collaborative knowledge extrapolation rules based on the prediction and evaluation of the results caused by different decisions according to internal and external requirements, and realizing effective cognitive and decision execution support.

The growth of virtual space needs to rely on a large amount of data generated by the activities of physical space, and the value and capability of virtual space will be continuously enhanced under the self-growing system of CPS. Therefore, the real world and the virtual world are the relationships of mutual guidance and mapping.

The main battlefield of industrial metaverse application is in the 2B field, and she is painting a grand blueprint to realize the interaction and optimization between the real world and the virtual world through virtual reconstruction of the whole structure, the whole process, and the whole life cycle of the interactive objects we need to know and act on, based on CPS and in series with IoT, VR, AR, cloud, big data, AI, 5G, and blockchain technologies.

The industrial metaverse is a new ecology of deep integration between new information and communication technologies and the real economy represented by the Internet of Things, artificial intelligence, and digital twin.

The focus of the industrial metaverse is on knowledge and services, realizing the transmission of people’s knowledge, and making the scale of personalized and high-end services possible.

Thirdly, the foundation of the industrial metaverse is CPS, and the main battlefield of its application is in the 2B field. She is painting a grand blueprint, and although the distribution is uneven, the future is here.

Today we are far from seeing the full picture of the blueprint of the industrial metaverse, but the future is here.

Besides the What is Industrial Metaverse article, you may also be interested in the below articles.

What Is The Core 5G NR Technology?