Today, we talk about the Top 5 industrial IoT use cases in 2021.

As more organizations adopt the IIoT (Industrial Internet of Things), the technology will lead to more innovation and further improvements in industrial IoT use cases such as predictive maintenance and workplace analytics.

The rapid adoption of the Industrial Internet of Things has been driven by organizations looking to take advantage of the latest technology.

While IIoT is still relatively new and faces some challenges, the technology can provide a competitive advantage to those who successfully implement it. Top industrial IoT use cases to highlight the value of these technologies.

IIoT applies wireless technology to industrial environments. Most often, IIoT means adding remote sensors to robots or long-haul trucks, but organizations can also use the technology for a wide range of purposes. The data-driven fourth industrial revolution, or Industry 4.0, relies on IIoT to handle a wider range of data collection and communication.

According to market and market reports, the global IIoT market is worth $76.7 billion in 2021, and experts predict it will exceed $100 billion by 2026. While manufacturing is not the only area utilizing these technologies, it is largely driving this growth.

According to a 2020 survey by the Society of Manufacturing Engineers, a professional association, and AI-based IIoT software providers, more than 66 percent of manufacturers say IIoT is critical to their success.

Benefits and challenges of the Industrial IoT use cases

Industrial IoT use cases extend connectivity and increase visibility. With more real-time insight into their operations, organizations can make more informed optimization decisions. These connections also improve efficiency by establishing remote access.

Machines with IIoT sensors can communicate with each other, making automation systems more flexible. Just as wireless real-time data can improve human response times, it allows machines to recognize and adapt to changing conditions. IIoT devices can also reduce energy consumption by adapting to use only what they need.

Despite the advantages, IIoT applications also pose challenges. Most notably, more network endpoints can increase an organization’s attack surface and vulnerability. An organization’s reliance on endpoint devices makes attacks more devastating. Other potential issues include high upfront costs and initial disruptions caused by new technology implementations and changing workflows.

As IIoT becomes more widespread, these technologies will become more accessible and affordable, and the benefits can offset the initial costs. Stricter cybersecurity standards can address growing cyber threats, such as the information security standard ISO 27001, which provides a framework for mitigating data breaches.

How can organizations use IIoT?

With these benefits and challenges in mind, here are five leading industrial IoT use cases that organizations have gained from today.

Predictive Maintenance in Top 5 industrial IoT use cases

Predictive maintenance is one of the most popular use cases for IIoT. Organizations use wireless IIoT sensor data to predict when machines need maintenance and alert workers. This IIoT use case prevents costly breakdowns and unnecessary repairs and increases machine uptime.

Implementing predictive maintenance has saved some organizations up to tens of millions of dollars by reducing downtime. Any organization that relies on expensive machineries, such as a manufacturer, trucking company, or construction company, can realize significant savings from using IIoT.

For predictive maintenance to provide these benefits, analytics must be available with sufficient data. Finding and installing the necessary IoT devices to accurately collect information can take time and have high upfront costs. Because of these challenges, smaller facilities may have difficulty implementing predictive maintenance.

Location Tracking in Top 5 industrial IoT use cases

Location tracking using GPS systems, RFID tags, and other wireless technologies can show organizations the location of their assets at all times. This transparency promotes increased efficiency.

Logistics companies often use location services to track shipments and reschedule drivers in the event of an obstacle. Warehouses and manufacturing centers can also use location-based IIoT technology to show workers where materials are located. Real-time, accurate location data eliminates confusion and employees can find what they need faster.

One of the biggest obstacles facing location tracking systems is network coverage. Facilities need consistent, reliable connectivity to support real-time data across multiple assets, which organizations may not have. Upgrading to a more reliable, higher bandwidth network using wireless technologies such as 5G can improve connectivity, but at an additional cost.

Workplace Analytics in Top 5 industrial IoT use cases

As more IIoT devices are put in place, organizations will have access to more workflow data. Data scientists can feed data into analytics engines to find inefficiencies and suggest ways to optimize operations. Location data analytics can also highlight inefficiencies in warehouse organizations.

Similar to predictive maintenance, these IIoT applications require large amounts of reliable data to be effective. Before these analytics can provide useful and accurate insights, facilities will need to implement large IoT networks and collect data over time. They will eventually provide a positive ROI, but it will take time for this to happen.

Remote Quality Monitoring in Top 5 industrial IoT use cases

Organizations such as the Environmental Protection Agency use IoT sensors to monitor the quality of resources and products, such as water quality. Sensors can provide information about contaminants more quickly and cost-effectively, leading to faster and more efficient responses. Industrial organizations that rely on quality monitoring processes can apply IIoT to the same effect.

A chemical processing plant or pharmaceutical company can use IoT sensors to remotely monitor material or product quality. Remote monitoring can increase productivity when staff can check multiple processes in rapid succession.

Likewise, real-time alerts prompt faster responses, reducing accidents that could jeopardize products if left unchecked for long periods of time.

Because remote quality monitoring is a relatively new concept, products and services do not exist off the shelf for every use case. Organizations may have to develop proprietary IoT technologies to measure the metrics associated with them, which can be both expensive and challenging.

Energy Optimization in Top 5 industrial IoT use cases

A perhaps less glamorous but equally valuable industrial IoT use case is energy optimization. Connecting IoT to industrial machines, HVAC systems, or any device that uses a lot of electricity can reduce energy consumption.

IoT sensors can detect peaks and valleys in energy use and automatically adjust operations to use as little electricity as possible.

Considering how the industrial sector accounts for 33% of total U.S. energy consumption, the potential for energy savings is huge. Manufacturing is probably the most common target for these IIoT-based improvements, but any company that uses electricity can take advantage of the savings.

The industrial IoT use cases have proven the technology can be effective in reducing energy consumption, but these savings are often negligible. In the absence of mechanical upgrades, power optimization can only go so far in reducing the associated costs. If organizations want to achieve significant energy savings, they must implement additional technology on top of IoT sensors.

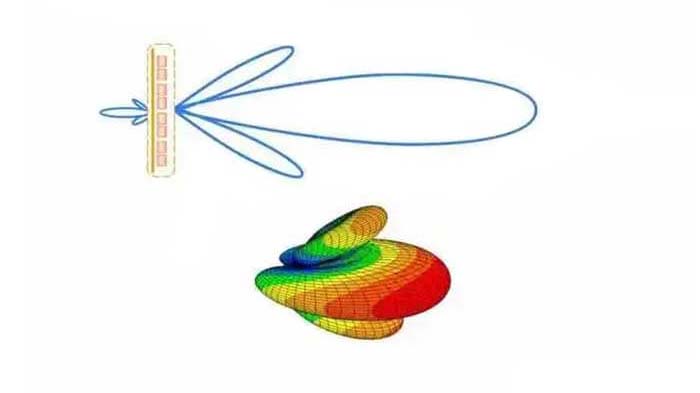

If you have any IoT antenna questions, please read our ANTENNA FAQ section, if you still cannot get the answer you need, please contact us.

You may also be interested in the below articles.

What Is The Core 5G NR Technology?