This article is an analysis of the value of IoT business applications for equipment manufacturers.

With the influx of IoT devices and process data, equipment manufacturers in the industrial sector find themselves at a crossroads of disrupting or being disrupted.

Widespread interconnectivity powered by IoT technologies opens up new avenues for previously unattainable value creation. For equipment manufacturers, this means they need to rethink their operating models or risk losing out on market opportunities as their digital businesses expand rapidly.

For IoT device manufacturers, the opportunities of IoT are limitless as they cover everything from improved maintenance services and aftermarket opportunities to innovative revenue generation and enhanced product design.

All of this is made possible through a new range of machine telemetry data provided by embedded IoT sensors.

By leveraging IoT business applications’ massive data collection and deep analysis, equipment manufacturers can transform their operating models while activating new products and services to better serve their industrial customers.

Value 1 of IoT Business Applications: Equipment O&M and Aftermarket

After-sales services, whether selling and replacing spare parts, carrying out repairs and maintenance, or installing upgrades on machines, represent a significant source of revenue and also contribute to an optimal customer experience.

Managing these services is by no means an easy task. Once the equipment has been sold, the equipment manufacturer has little visibility of its operation on the customer’s premises.

Machine failures are only known after tangible and/or serious damage. But even then, time-consuming manual checks of individual components may still be required to find the root cause of a failure.

The inability to know exactly when a machine needs to be repaired after commissioning also poses spare parts inventory management challenges for equipment manufacturers. This can lead to obsolete assets due to overstocking, or worse, delayed response due to out-of-stock. The latter will mean increased downtime and astronomical cost charges for customers.

The IoT business applications can help equipment manufacturers and their customers address these challenges by helping them transition from reactive to proactive asset management.

By using IoT sensors to continuously capture critical asset data and transmit it to a cloud-based analytics platform, equipment manufacturers can easily monitor equipment from a distance. As a result, anomalies and inconsistencies can be quickly monitored and failure points pinpointed.

This, in turn, facilitates spare parts ordering and troubleshooting workflows to minimize production disruption and asset downtime.

Condition-based or predictive maintenance is indeed an innovative value-added service that differentiates the equipment manufacturer’s offering from any other aftermarket supplier.

At the same time, IoT business applications’ digital data reporting of asset operations further enhances the customer experience through improved quality control and advisory services.

For example, equipment manufacturers can use IoT business applications’ machine data to perform in-depth analyses of global failure causes to provide users with advice on how to reduce future risks.

Value 2 of IoT Business Applications: Innovative business model - equipment as a service

In addition to delivering greater profitability through enhanced after-sales services, the IoT business applications allow IoT device manufacturers to capture entirely new business models through data-driven products.

Instead of selling equipment on a one-off basis, IoT device manufacturers can offer an option where customers can rent equipment and be charged for the time the equipment is used and/or the output. This model is known as Equipment as a Service (EaaS).

Through a subscription-based pricing strategy, EaaS offers clear advantages to both equipment manufacturers and industrial customers.

On the one hand, customers can replace high upfront capital costs with lower monthly or per-use payments and thus enjoy greater flexibility, lower risk, and easier-to-use equipment.

At the same time, IoT business applications’ maintenance and overhaul activities are fully covered by service level agreements (SLAs) and are better-guaranteed thanks to real-time data on machine operation.

On the other hand, equipment manufacturers can benefit from a steady, recurring revenue stream over the life of the asset, better customer engagement, and more opportunities for up-selling.

While the shift to EaaS is not without its challenges, its enormous potential is well recognized, with the global EaaS market expected to grow to US$131 billion by 2025.

Early adopters of this new flexible payment model are expected to gain a greater competitive advantage over other IoT device sellers.

Value 3 of IoT Business Applications: Predictive analytics and product optimization

Sensor data on device operation also reveals a wealth of insights into future product design that needs to be improved and refined.

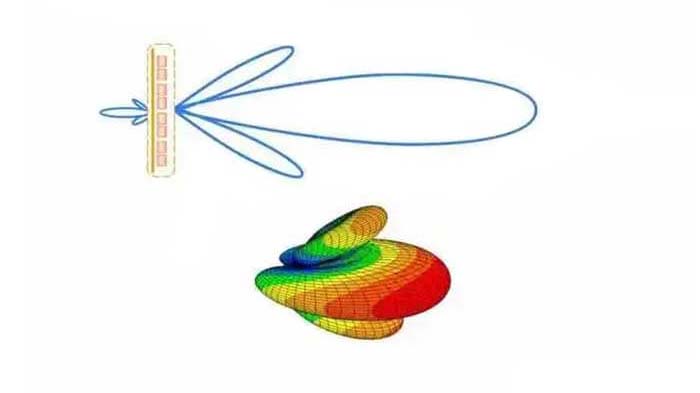

While product engineers may develop simulation models to evaluate the performance of assets in the field, their actual performance and output are highly susceptible to deviation due to a variety of unpredictable factors.

By monitoring the operation of the same equipment across different customer sites, equipment manufacturers can detect common component failures or bottlenecks such as small stops, long start-up cycles, or high energy consumption, and can therefore make relevant adjustments in future design specifications to mitigate these issues.

With the significant cost-saving opportunities that well-designed and efficient machines offer customers, device manufacturers can gain a unique leading position in the market, while increasing customer loyalty and retention.

The potential of IoT business applications for device manufacturers is immense as they can transform product-driven business models into service-driven business models, resulting in greater value delivery.

In this context, advanced sensor and IoT business applications’ networking technologies enable IoT device manufacturers to unlock new field data, enabling creative digital products and future innovations.

Besides the 3 Values of IoT Business Applications For Equipment Manufacturers article, you may also be interested in the below articles.

What Is The Core 5G NR Technology?