Today, we are going to talk about the top 10 cost factors affecting the mass production of IoT hardware.

What is IoT hardware?

IoT hardware is a critical component of a full IoT solution. Understand how a smart device acquires, processes, and communicates data to the Cloud. In IoT, hardware and software work together across the IoT Technology Stack. And managing hardware products requires very different skills than managing software.

There is no doubt that production costs are one of the most critical expenditures when bringing new IoT hardware products to the market.

You need to know what your IoT hardware production costs are in order to set your retail price, and most importantly, determine your profit margin.

I need to explain 2 terms first. Production cost refers to the cost you pay to produce the product; landing production cost refers to the production cost plus the cost of transporting each product to your warehouse. It is also called the cost of sales.

If your business is successful, then you will establish a long-term and intimate relationship with these numbers. You will always work to reduce them so that you can maximize your profits.

Most companies have to wait until the product is fully developed before attempting to estimate production costs. This is a serious mistake. You need to know the production cost of the product as early as possible, and you don’t want to spend years developing a product that is not profitable.

The cost of producing IoT hardware

If you are making IoT hardware products, then these are the production costs you need to know.

1. Electronic components

The cost of electronic components will be the most difficult to accurately estimate. The selection of all electronic components (mainly microchips and other key components) requires a lot of engineering design.

The selection of all major electronic components is crucial to accurately estimate production costs. You need a list of materials, listing all the required electronic parts.

2. Printed circuit board (PCB)

Two steps are required to produce electronic products. First produce an empty printed circuit board (PCB), and then solder the electronic components on it.

The cost of an empty PCB is mainly determined by the number of wiring layers and the size of the circuit board. At least two wiring layers are required, but most designs require four to six. A complex design may require eight or more. The more layers used for wiring, the smaller the circuit board size.

3. Plastic parts

Although the cost of the injection mold itself is quite expensive, the cost of the plastic parts produced is quite low. The type, size, weight, and molding time of the plastic used determine the cost of plastic parts. Your product design determines the molding time, size, and weight of any plastic part. There is only one option left to reduce the cost of your plastic parts without affecting your design: multi-cavity molds.

The use of multi-cavity molds can increase production speed and reduce part costs. The disadvantage is that multi-cavity molds are much more expensive than single-cavity molds.

4. Final product assembly

After the various components (assembled PCB, plastic housing parts, etc.) are ready, the next step is to assemble everything into the final product. The final assembly cost is almost entirely composed of labor costs. In the end, you may need to assemble in Asia, where labor costs are much lower.

5. Test

Once the final product is assembled, the product must be tested to confirm that it functions properly. Incorrect testing will eventually ship bad products to customers. This is a fatal mistake that may kill your startup. High-level testing is essential to provide quality products.

6. Scrap rate

Since there is no perfect production process, you will definitely have some problematic products. Initially, the scrap rate may be 10% or higher. However, as the production process improves, this proportion should eventually drop to 1-3%.

7. Retail packaging

Will your products be sold online or in physical retail stores?

Retail packaging is not so important for products sold online, because the packaging is mainly to protect the product from damage during transportation.

On the other hand, when selling in a retail store, the packaging is as important as the product, because the packaging itself must sell the product.

Fine retail packaging can be very expensive, so it’s usually best to start with something simple to minimize costs. This is one reason why it is best to focus on online sales in the first place.

Online sales will also give you more flexibility because it is much easier to adjust the sales information on your website than to adjust the physical packaging.

8. Return and exchange goods

Like the scrap rate, you have to accept that a certain percentage of products are returned by customers. You need to include it in your cost of sales estimate. Likewise, just like the scrap rate, when you improve your products, packaging, and customer service, the return rate should drop significantly.

9. Freight

Most consumer hardware products will eventually be produced in Asia. This means that the finished product must be transported by truck from the factory to the local seaport, where it is loaded on a cargo ship. Then, you must use trucks to transport the products from your local seaport to the warehouse or customer.

10. Taxation

Don’t forget about taxes! Both the importing country and the product-producing country will levy tariffs on you. Fortunately, certain product categories are exempt from import and export duties.

Summary

Pay special attention to not waiting until the product is fully developed before estimating the IoT hardware production cost. Any large IoT hardware companies that develop new IoT hardware products will estimate the IoT hardware production costs before starting development, and so should you.

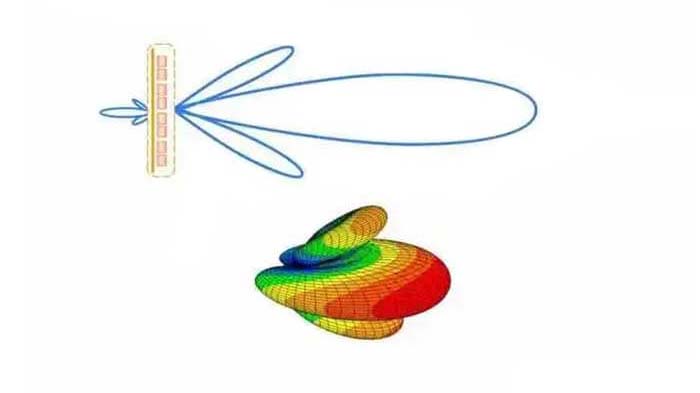

If you have any antenna questions, please read our ANTENNA FAQ section, if you still cannot get the answer you need, please contact us.

You may also be interested in the below articles.